LB-Co-Tonjolan lapisan ganda wpc garis Tonjolan profil

bahan baku + kakuatan kai + aditif → Pergaulan → granulating → kerucut kembar-screw extruder → kapang Tonjolan profil → tiis molding paeh → rojongan calibration vakum → haul-off → cutter → rak → produk rengse

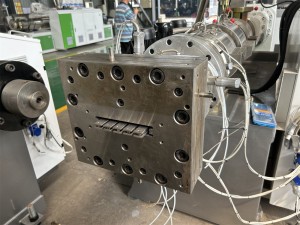

1> Conical Double screw extruder: SJSZ-65/132

2> WPC PP / PE / PVC jandéla, panto, Anggar, decking, skirting, floor profil kapang

3> Sistim calibrating vakum

4> Angkat kaluar mesin

5> Mesin motong

6> bracket ngurangan

7> Adun

8> Mesin Embossing

| Modél Extruder | SJZ55/110 | SJZ65/132 | SJZ80/156 | SJZ92/188 | ||

| Daya motor (kw) | 22 | 37 | 55 | 110 | ||

| lebar produk | 200 | 240 | 300 | 600 | 900 | 1200 |

| kakuatan vakum | 4kwx1 | 5,5kwX1 | 5,5kwX1 | 5,5kwX2 | 5.5kwX1 7.5kwX1 | 5.5kwX1 7.5kwX1 |

| pompa cai | 2,2kw | 2,2kw | 4kw | 5kw | 7,5 kw | 7,5 kw |

| Laju angkot | 0-5m / mnt | 0-5m / mnt | 0-5m / mnt | 0-3m / mnt | 0-2,5m / mnt | 0-2,5m / mnt |

| Kapasitas (kg/h) | 70 kg/jam | 110 kg/jam | 110 kg/jam | 170 kg/jam | 300 kg/jam | 300 kg/jam |

| Beurat Net (kg) | 3000 | 5000 | 6500 | |||

Upami bahan baku nyaéta pe atanapi PP, anjeun kedah nyampur bubuk kai + partikel PP / PE babarengan, teras nempatkeun kana garis pelletizing, tungtungna nampi pellets palastik kai final.